Fast and efficient retention of polluting liquids

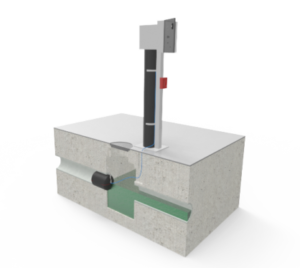

The underground pipe sealing system designed by the LCF Technologies team aims to prevent any industrial liquid pollutant generated from cleaning, fire-extinguishing water or uncontrolled spills from reaching the public sanitation network.

WHAT IS A PIPE SEALING SYSTEM?

Our pipe sealing system is based on the physical installation of a shutter in the headers/pipes exiting the pit/tank pneumatically connected to a compressor/bottle.

When activated automatically, remotely or locally, the compressor/bottle inflates to seal/shutter the headers/pipes, thus preventing contamination.

The activation of the compressor/bottle to inflate the shutter can be manual, remote and/or automatic, and its particular components will depend on the technical requirements of each installation.

Once the spill/contamination risk has been checked and resolved, the shutter deflates and returns to its initial rest position, allowing liquids to pass through in normal conditions.

WHAT TYPES OF ACTIVATION ARE AVAILABLE?

Local activation

Every shutter is controlled from a control panel located nearby.

Automatic activation

The shutter activates automatically via an electrical signal from the activation of the fire alarm system or a similar device or system. All the elements can be controlled locally through the control panels and remotely using a push button in a strategic location chosen by the customer.

Remote activation

The shutters can be activated by a remote push button in a location chosen by the customer.

Benefits of automatic and manual spill barriers

LCF Technologies spill barriers are designed to function in emergency situations and ensure watertightness at all times. They have many benefits compared to other alternatives, such as:

- Manufactured in-house in Spain

- VdS Certification

- Fast installation

- Versatility

- Autonomy

- Reliability

- Fast action

- Convenience

LCF Technologies spill barriers can be made to order in stainless steel or ATEX. And they adapt to any situation.